Mohawk Lifts TP-18 18,000 Lb. Two Post lift

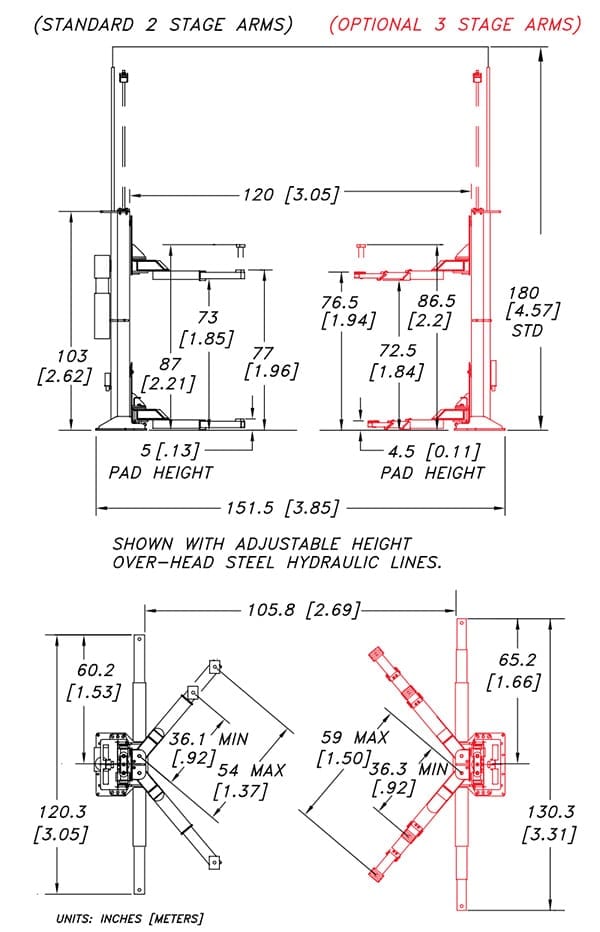

7′ 3” Column Height, 6′ 5” Rise

7′ 3” Column Height, 6′ 5” Rise

12′ 7-1/2” Overall Width / 12,000 lb. Capacity

Stocked Locally in Farmingdale, NY

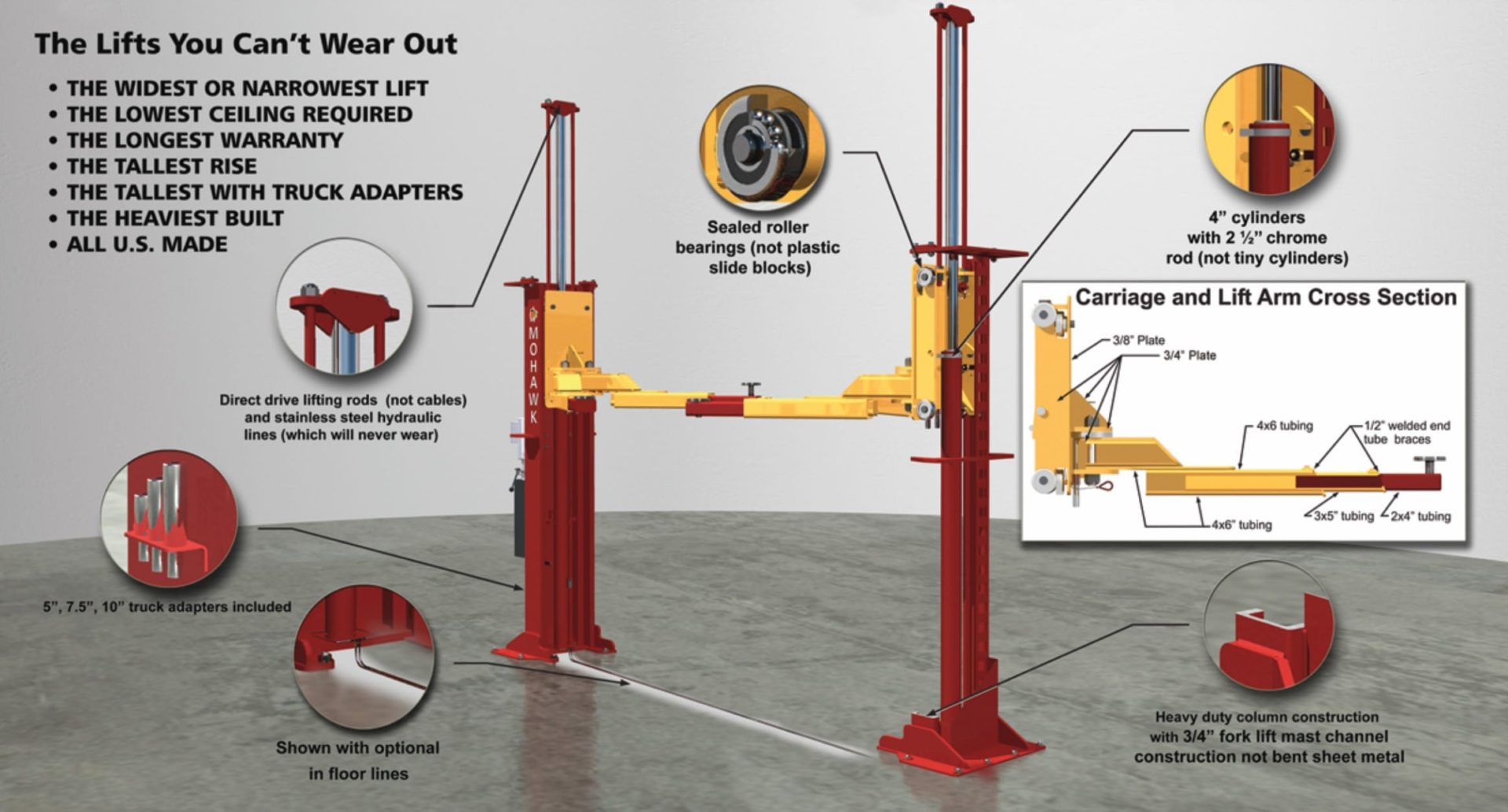

MOHAWK 18K 2 POST LIFT DESIGN

- Mohawk’s two post lift columns are constructed of 3⁄4” thick forklift masts, for a lifetime of trouble-free service.

- Each Mohawk two post lift features a carriage that rolls on 8 double-sealed, self- lubricating steel ball bearing rollers. Not plastic slide blocks.

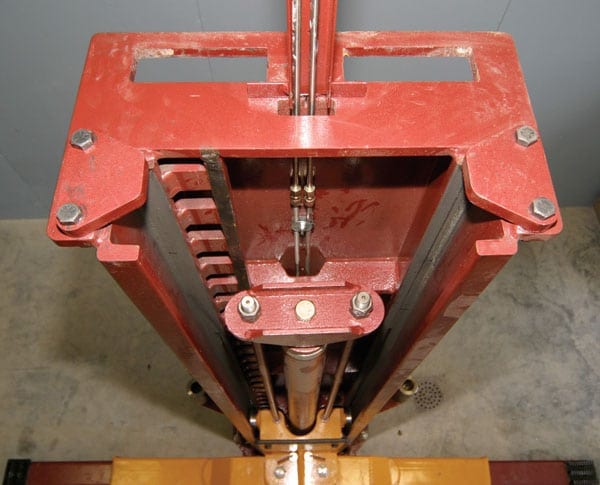

- The Mohawk TP-18 2 post lift features two [2] large 4” heavy duty cylinders which make for safer, steadier lifting than single cylinder lifts or competitive brands with smaller cylinders.

- Mohawk’s 18,000 lbs two post lifts come standard with low profile three stage swing arms that retract an additional 2” (1” each side) shorter and offer additional 10” extension for varied fleets.

- Easily adjustable overhead stainless steel hydraulic lines can be set at any height (or routed in floor) to accommodate all tall trucks and vans.

- 60 second lifting speed saves shops time and money.

- Low profile 5” swing arms fit under most passenger cars.

- Mohawk Heavy Duty two post lifts come standard with 5”, 7-1⁄2” and 10” pad height extensions/stack adapters.

MOHAWK’S PATENTED INDUSTRY-LEADING 2 POST LIFT SAFETY SYSTEMS

- Mohawk two post lifts feature all position mechanical safety locks in both columns, starting at the ground, to full lifting height of 6’.

- Patented infinite position, internal hydraulic safeties, backed by external pressure compensated flow controls and velocity fuse valving.

- Swing arm restraints automatically engage upon lifting, and automatically disengage when the vehicle has been fully lowered.

- The best and most inclusive warranty in the lift business, 25 years structural, 10 year mechanical, plus limited lifetime cylinder seal warranty. Mohawk builds the best two post lifts, with the best warranty.

- Lease/purchase plans available for 1-5 years. Call Ace Service & Installation 631-694-0220 now!

HEAVY DUTY 2 POST LIFT OPERATION

- Hydraulic fluid is pumped between the two cylinders through the overhead (or optional in-floor) stainless steel hydraulic lines. Patented hydraulic synchronization eliminates the need for restrictive height overhead covers, cables, pulleys, equalizer chains or obstructive floor plates.

- To raise the carriages, Mohawk’s TP-18 two post lift uses direct drive lifting rods which eliminate the wear & maintenance associated with lifts that use cables, chains, & overhead cable covers.

- Mohawk carriages roll on eight double sealed, self- lubricating, steel ball bearing rollers, for a lifetime of maintenance-free operation.

- Mohawk bearings last longer, with less friction and wear than competitive lifts using plastic slide blocks which need constant greasing and maintenance.

100% designed, welded, and manufactured in the U.S.A.

MOHAWK TP-18 FEATURES

Mohawk’s Heavy Duty Two Post Lifts offer FULL unobstructed under vehicle access for all repairs, take up minimal bay space and leaves wheels hanging free for tire, brake or any other necessary repairs.

Mohawk’s TP-18 features a large and stable footprint measuring 30” wide by 24” constructed from 3⁄4” thick plate. Mohawk’s large base gives stability to the lift, while distributing the load to the shop floor.

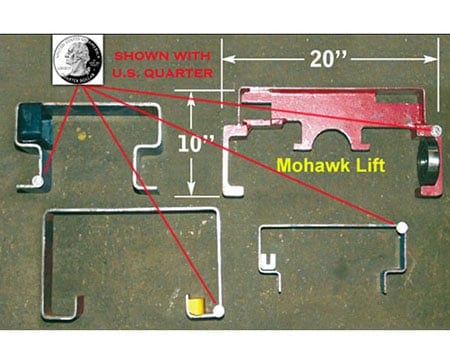

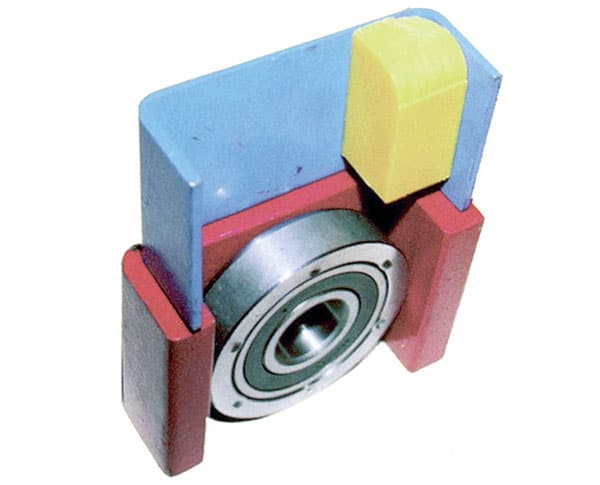

Mohawk’s forklift channel & bearing (top right) VS. 3 different competitive columns which use bent sheet metal and plastic slide blocks. Like the mast on your forklift, Mohawk Lifts DO NOT WEAR OUT!

=

=

Heavy duty column construction with direct drive cylinders, direct drive lifting rods (not cables) and stainless steel hydraulic lines (not rubber hoses) which will never wear.

Each Mohawk TP-18 two post lift features a carriage that rolls on eight [8] 4” double sealed, self lubricating, heavy duty ball bearing rollers for a lifetime of trouble-free service (not plastic slide blocks).

Mohawk’s TP-18 two post lift has ALL position 1” thick mechanical locks on BOTH carriages that engage for the full length of travel. Available with optional single point air lock release (requires air to lift).

This photo shows Mohawk’s cylinder size vs competitive brands. It’s pretty simple: LARGE 4” CYLINDERS = longer seal life and lower operating pressures than smaller competitive cylinders. There’s a reason Mohawk Lifts offers the best warranty in the business!

We know you’ll be lifting heavy vehicles! That’s why Mohawk Lifts come standard with 5”, 71⁄2” and 10” stacking adapters (for hard to reach frames).

This photo shows Mohawk’s FORK LIFT CHANNEL & bearing (bottom) vs. competitive columns & plastic slider (top). Plastic slide blocks will wear out over time. Mohawk’s sealed roller bearings have a significantly longer life span.

Mohawk’s TP-18 comes standard with 3-Stage Arms for varied fleets.

SPECIFICATIONS

| Model | LMF-12 | TP-16 | TP-18 |

| Capacity | 12,000 lbs. | 16,000 lbs. | 18,000 lbs. |

| Lifting Speed | 60 seconds (faster with lighter vehicles) | ||

| Motor Rating | 4 HP/208-230V, Single-phase (3ø optional) | 4 HP/208-230V, Single-phase (3ø optional) | 4 HP/208-230V, Single-phase (3ø optional) |

| Synchronization | Hydraulic fluid displacement using no chains, cables, or overhead obstructions | ||

| Arm Pad Height | 5" min. | ||

| Lifting Height (Stroke) | 6' under arm | ||

| Arm Pad Height at Full Rise | 6'5" | ||

| Max. Arm Pad Height with Adapters | 7'3" | ||

| Overall Width | 12' 7-1/2" (adjustable) | ||

| Width Between Posts | 10' (adjustable) | ||

| Width Between Lifting Arms | 8' 9-1/2" (adjustable) | ||

| Column Height | 8' 7" | ||

| Overhead Hydraulic Line Height | 15' Standard (adjustable to accommodate any height ceiling or routed in-floor) | ||

| Weight | 3100 lbs. | 3600 lbs. | 3900 lbs. |

| Concrete Floor Requirements | 4000 psi mix 6-1/2" depth | ||

| Anchoring System: Included | (16) 3/4” x 6” bolts | ||

| Mechanical Safety Locks | Automatic; mult-position starting @ 5” off the floor | ||

| Hydraulic Safety Systems | Automatic; all position | ||

| Swing Arm Restraints | Automatic upon ascent | ||

| Cylinders | 2 (1 per column) | ||

| Drive System | Direct drive (using no cables or chains) | ||

| 5" Frame Adapters (stackable) | 4 included as standard equipment | ||

| 7-1/2” Frame Adapters (stackable) | 4 included as standard equipment | ||

| 10” Frame Adapters (stackable) | 4 included as standard equipment | ||

| Steel Carriage Bearings | (16) 4” diameter (8 per carriage) double sealed, self-lubricating ball bearing rollers | ||

| Floor Access Between Posts | Clear and Unobstructed | ||

| Warranty | 25 years structural, 10 year mechanical warranty |